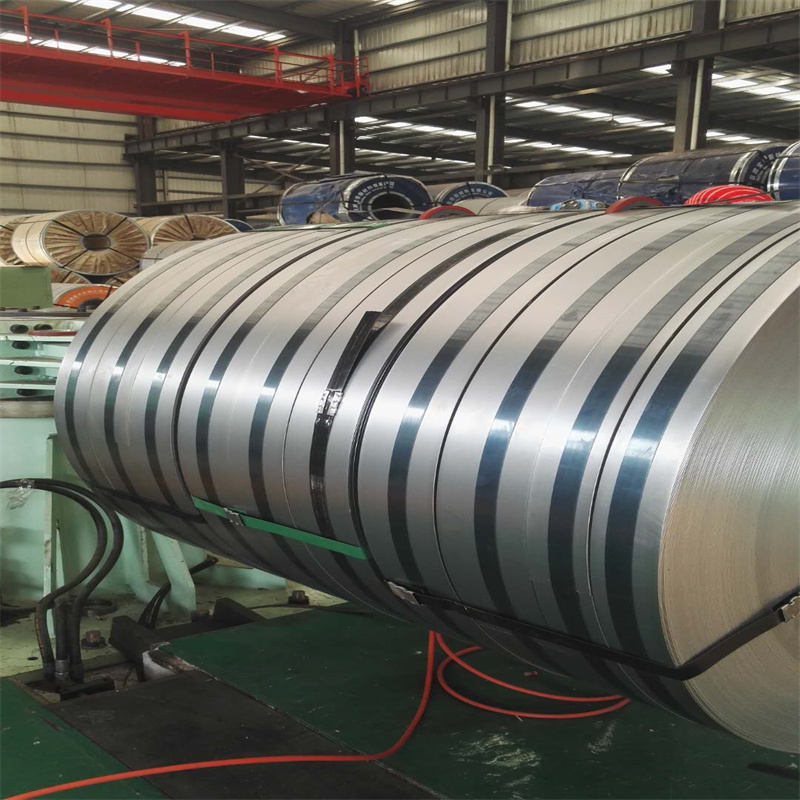

Spiral pipe, also known as spiral steel pipe or spiral welded pipe, is made by rolling low-carbon structural steel or low-alloy structural steel strip into pipe blank according to a certain angle of spiral line (called forming angle), and then welding the pipe seam. It can produce large-diameter steel pipe with narrow strip steel.